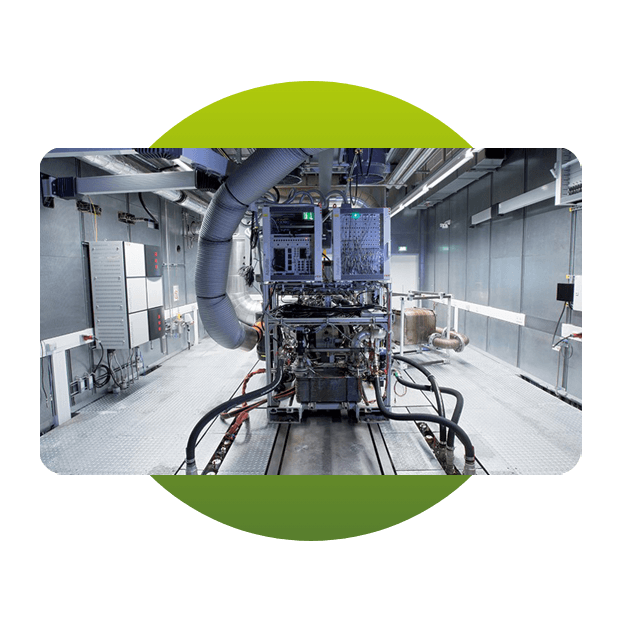

ENORISE Develops Engine Test Benches

Modern engine test benches often need to perform complex test methodologies while maintaining high efficiency goals.

As a powertrain engineering provider, ENORISE excels in powertrain testing methodologies.

ENORISE test bed solutions, originally designed to meet the company’s own needs, offer unique capabilities for conducting complex engine tests with high efficiency.

Thanks to the modular design, these solutions are flexible, ranging from turnkey test cells to easy refurbishment of existing test cells.

Engine Test Bench for Passenger Cars: Maximum Operational Time

The engine test benches for passenger cars cover a wide range of scenarios: From the single test bed of an independent research center to multiple test beds working together in an OEM test center. Several standard solutions have been developed to meet general requests, while the expertise gained from our test centers allows us to address more specific testing needs.

Characteristics

- Durability, calibration, R&D and more: Comprehensive testing solutions

- Generic testing for all types of engine performance

- Easy interface with all major test equipment

- Efficient application of models on the test benches

- Compliant with ASAM-MCD3 standards

Benefits of the Engine Test Bench for Passenger Cars

- Time saving: Generic test procedures for fast results

- Enhanced productivity: Simultaneous sequencing of tests for continuous performance

- Modular and flexible: Customizable configurations for diverse testing needs

- Dynamic testing: High-performance dynamometers (1 to 5 kHz, or more on request)

Fully Packaged Solutions for New Standards

The market for heavy-duty engine test beds is evolving rapidly. With the globalization of the market and increasingly ambitious environmental goals, test centers are facing new challenges:

- A greater diversity of emissions standards increasing the number of test types and their complexity: Euro 6-7, US transient, JE05, WHTC and more.

- Increased demands on productivity, test bed rotation and operational maintenance.

ENORISE’s heavy-duty test bed solutions are based on a three-pronged approach:

- Open and packaged test bed automation systems

- Reliable and efficient test bed equipment

- Modular test bed utilities designed by ENORISE

Benefits of Our Heavy Duty Test Bench Solutions

- Operational: Maximum operational time due to the reliability of the solutions and no engine stop during modifications.

- Proven: Over 1200 test beds installed with automation systems. More than 600 complete test beds installed: automation, dynamometers, commissioning, etc.

- Packaged: On-road and off-road applications fully automated for global, European, North American, and Japanese regulations.

- Expert: Experienced test bed engineers with expertise in shaft line and bearing calculations.

- Dynamic: High-performance asynchronous machines for both passenger car and heavy-duty engines.

- Modular: Modular design of test bed utilities (ventilation, exhaust extraction, fluids, etc.).

- Simulation friendly: Seamless integration of simulation models on the engine test bed.