Automatically Qualified End-of-Line Testing

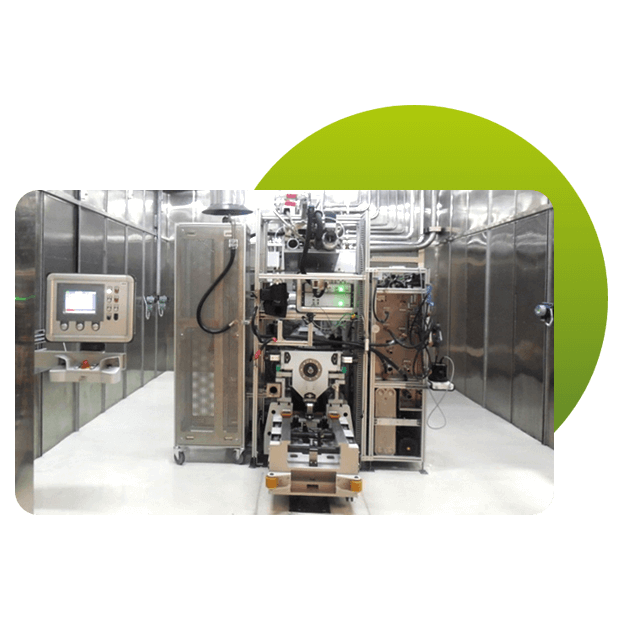

Quality assurance and control in engine and component production place high demands on the respective end-of-line testing facilities. High reliability, repeatability and a high degree of automation for mechanical processes, including the test run itself, automatic docking, filling and draining of the test object, as well as effective control and data management systems, are core characteristics of the production hot test facilities provided by ENORISE.

Why?

We cover a wide range of applications from small gasoline engines to large heavy-duty engines and offer diverse types of handling equipment, from largely manual operations to fully automated conveyor and distribution systems.

Common to all applications are our field-tested components, proven in hundreds of applications worldwide, our design expertise allowing flexible adaptation to individual project and test object requirements, and our global after-sales and service network.

Our test cells are customized based on specific project and test object requirements.

Characteristics

- Low to high automation levels

- Minimal setup time

- Modular design

- Safe investment

- High flexibility

- High throughput rates

Benefits

- High reliability of the end-of-line testing facility (up to 98% uptime)

- Short cycle times with low investment requirements

- Appropriate levels of automation

- Consistent, reliable testing results

- Adaptability to various engine types

- Scalable extensions for increased production capacity

Additional testing solutions:

Highly flexible test cells designed to accommodate multiple engine variants within the same test cell. This type of cell is ideal for long-duration tests, as the rigging time is comparatively longer than with semi-automatic or automatic cells due to manual media and shaft connections.

Benefits of ENORISE End-of-Line Test Cells:

- High reliability of the testing facility (up to 98% uptime)

- High flexibility for test objects (supports over 10 engine variants within the same test cell)

- Efficient cycle times for low investment (Rigging time inside the test cell can be as low as 60 seconds)

- Reliable and consistent testing results

- Modular designs enable quick and easy extension to support increased production demands

- Proven components utilized in hundreds of applications worldwide

- In-house design expertise based on extensive testing and development activities

- Global after-sales and service network for fast support

These test cells combine the benefits of both Manual and Automatic Docking Systems, making them the preferred option for OEMs who need to test multiple variants within the same test cell while requiring a short setup time. Flexibility and quick changeovers are achieved through engine-specific rigging kits, which include media connections with engine-specific Quick Release Couplings and spine shafts.

Benefits of ENORISE End-of-Line Test Cells:

- High reliability of the testing facility (up to 98% uptime)

- High flexibility for test objects (supports over 10 engine variants within the same test cell)

- Short cycle times for low investments (rigging time inside the test cell can be as low as 60 seconds)

- Reliable and consistent testing results

- Modular designs enable fast and easy extension to accommodate expanding production needs

- Proven components utilized in hundreds of applications worldwide

- In-house design expertise based on extensive testing and development activities

- Global after-sales and service network for quick support

Highly automated end-of-line test cells with the shortest setup times are suitable for applications with short test cycles and minimal variation in the test objects. Media connections are made through match plates, resulting in minimal manual intervention within the cell. The trolleys and pallets can be transported on conveyors to further reduce manual effort.

Benefits of ENORISE End-of-Line Test Cells:

- High reliability of the testing facility (up to 98% uptime)

- High flexibility for test objects (supports over 10 engine variants within the same test cell)

- Short cycle times for low investments (rigging time inside the test cell can be as low as 60 seconds)

- Reliable and consistent testing results

- Modular designs enable fast and easy extension to accommodate expanding production needs

- Proven components utilized in hundreds of applications worldwide

- In-house design expertise based on extensive testing and development activities

- Global after-sales and service network for quick support