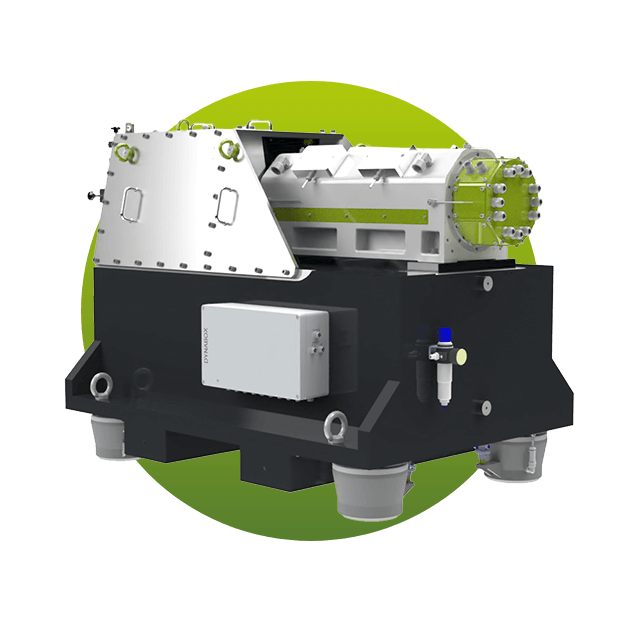

E-Motor test bench

Electric motor testing is essential to characterize the electric motor and inverter during the early stages of development. To achieve accurate results, tests must replicate real-world conditions, such as environmental factors (e.g., climatic chamber for temperature control) and driving simulations (including road conditions, driver behavior, etc.). The key feature of this type of test bench is its ability to operate at very high speeds and with dynamic performance, accounting for vibration during testing.

Why?

ENORISE designs and manufactures advanced electric motor test benches that meet the demanding requirements of e-mobility. Our dynamometers, packaging systems and custom solutions are tailored to meet specific customer needs. The MORPHEE® automation system offers unparalleled flexibility and ease of configuration for various test bench types. Currently, ENORISE has developed electric motor test bench solutions capable of achieving rotational speeds of up to 24,000 rpm and beyond.

Characteristics

- Dynamic test benches for electric motors with 24,000 rpm and higher

- MORPHEE® for e-mobility (automation, simulation and calibration)

- Preferred models for electric drive chains

- Multiple test bench architectures evaluated

- EtherCAT integration

- High accuracy for speed control at low speeds (0... 1,000 rpm)

- ECoolCon for water and oil conditioning with 1 to 3 circuits, including automatic filling and emptying

- OSIRIS Power Analyzer for detailed performance analysis

- Battery simulator for accurate load testing

- Optional: climatic chamber (temperature range: -40 to 120°C)

Key Benefits

- State-of-the-art solutions for electric motor testing

- Robust and validated products for reliability and precision

- Flexibility and scalability of MORPHEE®: a test bench that evolves with technological